- Undergraduate

Bachelor's Degrees

Bachelor of ArtsBachelor of EngineeringDual-Degree ProgramUndergraduate AdmissionsUndergraduate Experience

- Graduate

Graduate Experience

- Research

- Entrepreneurship

- Community

- About

-

Search

All Thayer News

Using Design Thinking to Disable the Threat of 3D-Printed Machineguns

Mar 27, 2025 | by Michael Blanding | Dartmouth Engineer

A Glock switch can be 3D-printed for 40 cents—and turn a gun into an automatic weapon. Dartmouth engineers are using design thinking to disable the threat.

The small piece of plastic looks harmless enough—a cube with a few holes and tabs sticking out in different directions—at worst a choking hazard for small children. In the wrong hands, however, it can kill or wound dozens of people in an instant.

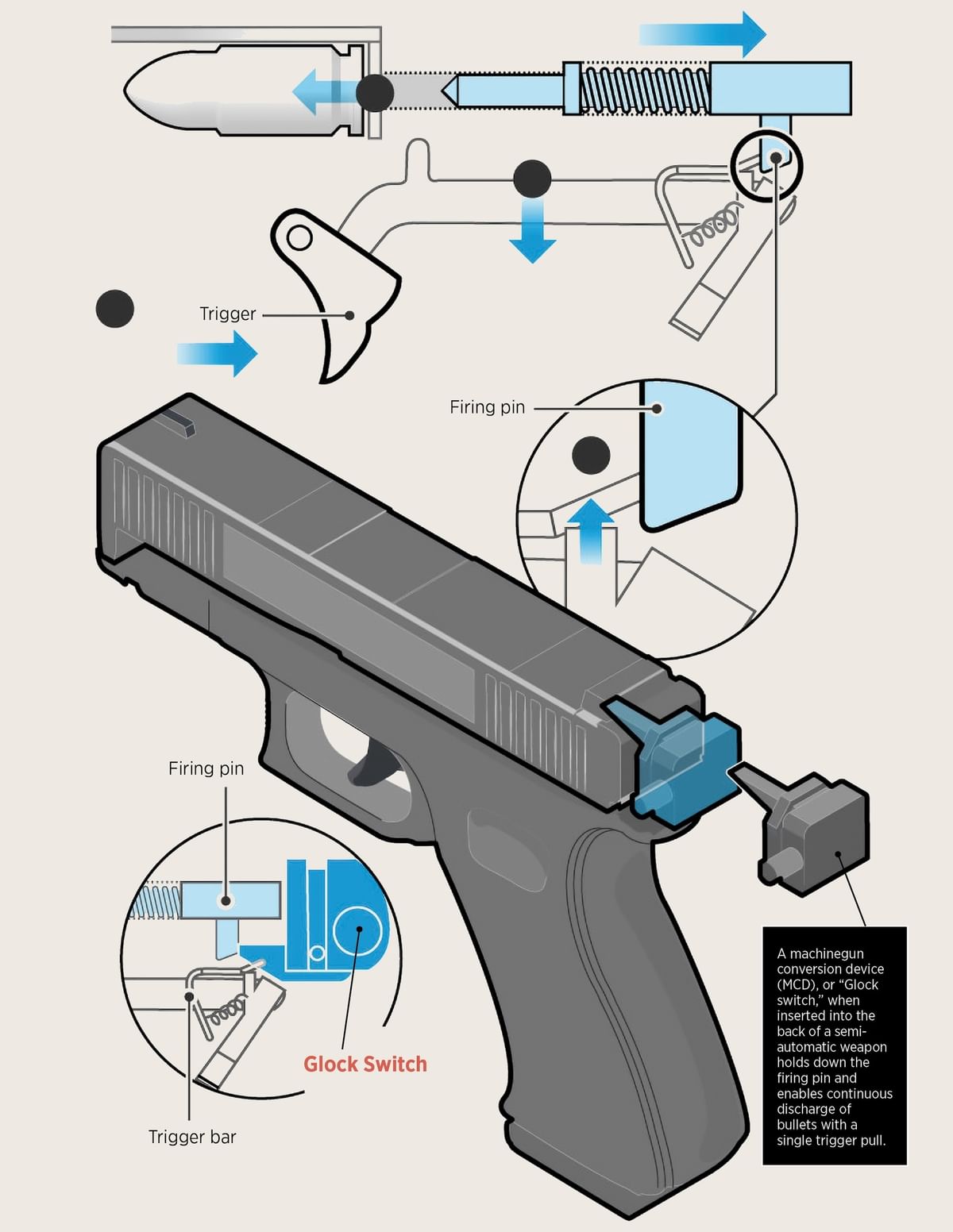

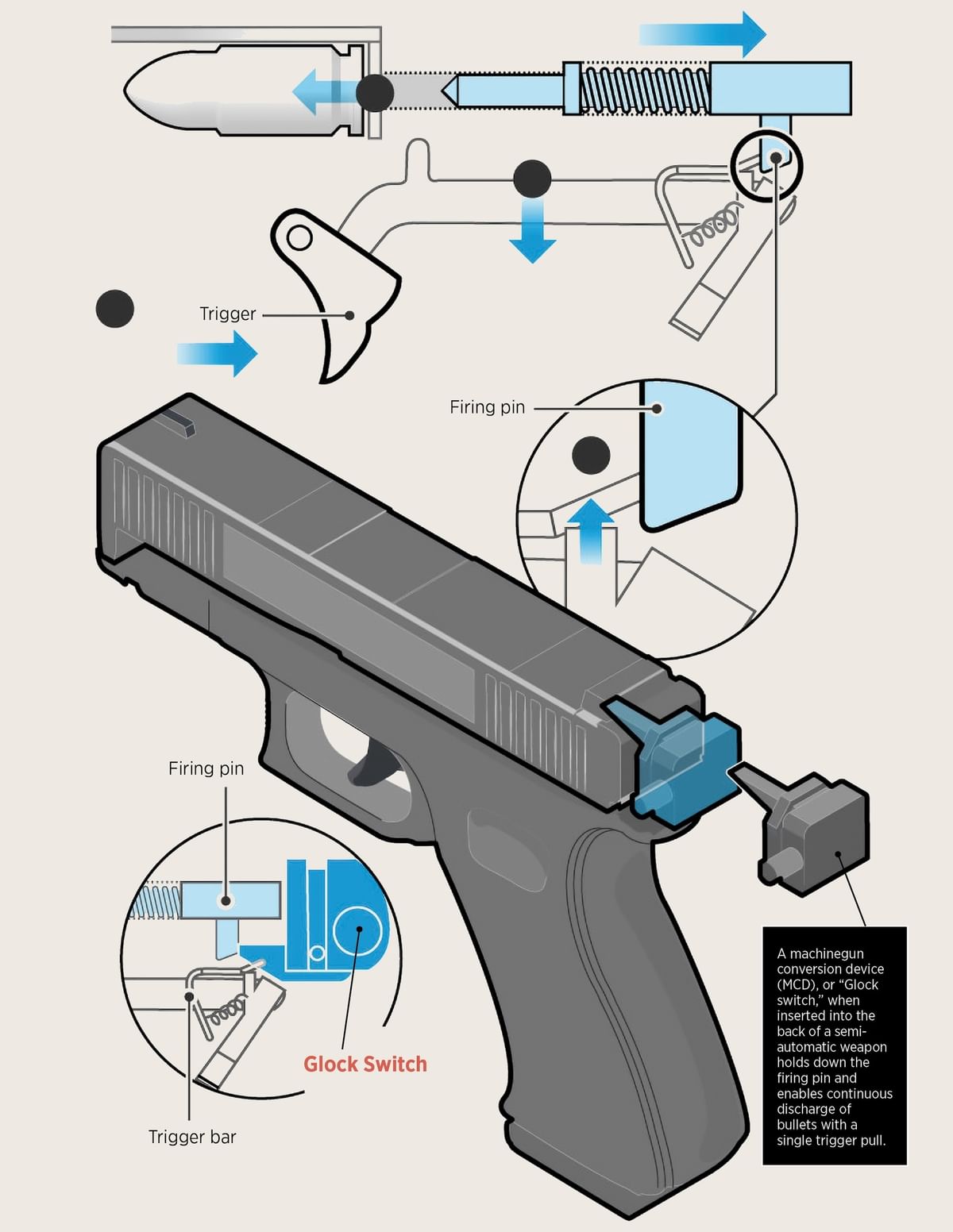

Known as a machinegun conversion device (MCD) or Glock switch, the object fits into the back of a semiautomatic pistol or rifle, transforming it into a fully automatic weapon that can spray up to a thousand rounds of ammunition with one pull of a trigger. Although MCDs are illegal in the United States, anyone can order them from the darker corners of the Internet for $20 or $30 each. Or worse, they can make one on a 3D printer for pennies.

"Gun violence is the leading cause of death for American children—not cancer, not car crashes—guns," Steven Dettelbach '88, former director of the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF) told an audience at Dartmouth last February, noting 43,042 people were killed and 36,336 injured by gun violence in the United States in 2023. Despite fully automatic weapons being outlawed a hundred years ago in the age of Al Capone and the Tommy gun, they have recently been making a dramatic return. "Thanks to the bad kind of tech innovation, the misuse of 3D printing," Dettelbach said, "machineguns are coming back to American streets."

While on campus, Dettelbach reached out to Alexis Abramson, then dean of Thayer, for help. Theoretically, 3D printers could be modified to prohibit the printing of MCDs—but could that be done in practice? And how could such a technological change be instituted on a nationwide scale? Abramson knew just where to turn: the Design Initiative at Dartmouth (DIAD), which she helped launch in 2021 to harness engineering know-how and design thinking to solve wicked challenges.

"DIAD's central hypothesis is that the methods and mindset of design can unlock desired futures where society is vexed right now," says codirector Sol Diamond '97 Th'98. "We're hungry for problems that we can solve with the human expertise and resources at Dartmouth." During the past year, he's led a project partnering with law enforcement, industry, and academia to tackle the complex issues—including technological, legal, commercial, and social—involved in getting MCDs off the streets. Along the way, Diamond and his team of faculty and students have proposed not only technological solutions to the machinegun problem but also a dramatic remaking of the 3D printing industry.

Thayer's Emily Monroe (second from left) and Professor Sol Diamond (far right) are introducing design thinking to students and the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF). (Photo by Rob Strong '04)

Humans at the Center

Diamond is uniquely suited to tackle the issue. A professor of engineering at Thayer, he has a background in biomedical imaging and taught courses in computer-aided design (CAD), including rapid prototyping through 3D printing. At the same time, he's applied an entrepreneurial mindset as CEO of medical imaging startup Lodestone Biomedical.

When Abramson contacted him, Diamond's first act was to pull in colleague Emily Monroe, director of Thayer's Cook Engineering Design Center (CEDC)—and a former engineer for firearms manufacturer Sturm, Ruger, & Co. and award-winning competitive target shooter.

They met over dinner with Dettelbach and his team to learn more about the issue. During the past five years, law enforcement has recovered more than 31,000 MCDs across the country, many printed at home by teenagers, and some used in horrific acts of violence—a drive-by shooting in Cincinnati in 2023 that left an 11-year-old dead and four other children wounded; a 2023 mass shooting at a "sweet sixteen" party in Alabama that killed four; a 2022 shooting in Sacramento that killed six; a police officer murdered in a hail of bullets while serving a warrant in Houston in 2021. Known variously as auto sears and chips, MCDs have become so common they are now found in the majority of illegal gun cases.

"For a lot of people, this is an everyday existence," says Monroe. "It's 13- to 19-year-old boys at home printing these things, dropping them into their parent's AR-15, and creating a military-grade weapon. It's just that easy."

Diamond and Monroe enlisted DIAD program manager Paula Olson, an expert on human-centered design with a background in human ecology and law, a "translator across disciplines" who takes a systems-level view of solving problems. The Dartmouth Engineering team then took a deep dive into additive manufacturing (as the 3D printing industry is known), including the hardware and software. Members reached out to sources at Thayer's MShop and makerspaces as well as "blitzing LinkedIn" to speak with more than 100 people from industry and law enforcement. "There was a lot of zooming in and zooming out, thinking, who is going to be at the meeting today, what are their needs? What are their alignments? What are their tensions?" Olson says.

"[The Design Initiative at Dartmouth's] central hypothesis is that the methods and mindset of design can unlock desired futures where society is vexed right now. We're hungry for problems that we can solve with the human expertise and resources at Dartmouth."

—Professor Sol Diamond '97 Th'98, codirector of Design Initiative at Dartmouth

For inspiration, the team examined other cases in which technology prohibited elicit material. Every inkjet printer, for example, has a feature that prevents it from printing counterfeit currency. In the early 2000s, peer-to-peer software such as Napster suddenly made it easy to download and share music files without authorization—until labels learned how to insert copyright-protected music files. That innovation led directly to today's streaming platforms such as Pandora, Spotify, and Apple Music, allowing consumers to play almost any song through a subscription. "Those market forces were critical to the digital music economy," Diamond says.

Intense research and interviewing are the first steps in the process of human-centered design, in which the goal is to empathize and understand the people for which a product or service is being designed. Then comes defining the problem, ideating solutions, creating a prototype, and further iterating based on feedback. "We teach ethnographic methods of interviewing and observing and identifying one's own assumptions before going out and doing anything," says Associate Professor of Engineering Eugene Korsunskiy, Diamond's codirector at DIAD.

As an engineering school within a liberal arts university, he says, Thayer is uniquely suited to teach those skills. "Whether you are designing physical objects or systems or organizations, it means being a creative and collaborative person who can harness the technological skills of innovation as well as the liberal arts skills from psychology and sociology to understand how people behave and what they value."

In the past two years, DIAD has built on the already formidable strengths in design at Dartmouth, which has offered a human-centered design minor for more than a decade. DIAD doubles down on those strengths with three pillars: spearheading new classes such as "Ethics in Design" and "Narrative Design for Innovators"; partnering with campus organizations to find solutions through Design Corps; and fostering societal impact through partnerships with government, industry, and nonprofits. "For us, human-centered design is the kind of creative problem solving that exists at the intersection of all the messy considerations of the technical, legal, and societal," Korsunskiy says.

"With this project, we are building an inspirational case study for students to see that you need the humanities and social sciences in complex technical problem solving. For liberal arts students who may not be sure what value they can bring to the world, we are showing that the skills they are gaining at Dartmouth are crucial."

—Professor Eugene Korsunskiy, codirector of Design Initiative at Dartmouth

Incentives for Solutions

The MCD problem fits smack dab in the middle of that crossroads. On a technical level, printing a 3D object consists of precisely forming layer after layer of material. The information making that possible exists within a computer file, usually in STL format, that includes the shape's coordinates sliced into layers that are transmitted to the machine through instructions called G-Code. If they were going to intervene to stop the process, Diamond and his colleagues realized, they'd have to identify the files leading to MCDs and stop the slicing before it occurred.

Tonia Cowan/The Wall Street Journal

With dozens of websites full of files by the thousands, that meant creating a process to identify the essential elements that make an object an MCD and distinguish it from a legitimate object. To do that, Diamond has employed statistics and image-processing techniques to flag the key components that make the various types of MCDs work, while ignoring those that don't. Diamond performed the analysis with the help of Jenna Martin '24 Th'25, who wrote an undergraduate thesis last spring on identifying MCDs from STL files, achieving about a 90-percent effectiveness on a sample of 35 files.

While continuing to refine those techniques, the team is also working on a web-based tool to help law enforcement identify MCD files. "Think about how challenging it must be for law enforcement, who confiscate a stack of SD cards with thousands of files and no way to figure out if there are MCD files on them or where they came from," Diamond says. His tool could help investigators by separating out the relevant files and tracing them to their source.

A more challenging endeavor is to modify printers to prevent them from creating MCDs. As they examined the issue, team members realized the technical aspects of integrating the identification software is only part of the problem—they also had to create industry incentives to implement the technology. "In trying to understand why this hasn't been solved already," Diamond says, "we realized there is no desirable, feasible, viable solution that people want, can build, and can make money from."

In considering what would make the technology viable, the team had another breakthrough—the same technology that can help identify and prevent MCDs could also prevent printing of proprietary material. That could, in turn, provide incentives for toy manufacturers and home crafters to create higher-quality plastic items that could be protected from copyright theft.

"If you had a file format that allowed for authenticated printing, you could have a whole new economic opportunity for consumers," says Diamond. "Anyone who made a printer that was compatible with that would be able to sell the printer for more money, because you're going to be able to print the highest-quality, authenticated parts that have been professionally produced and provided, not just the freemium stuff."

Such a solution was not what the team was expecting when it started examining the issue—but it represents the best aspects of human-centered design and its essential goal to take the needs of various stakeholders into account when creating a long-lasting solution. "When we zoomed out," Diamond says, "we saw the bigger picture of re-envisioning the entire industry."

Last September, their findings received a favorable reception at a convening in Washington, DC, with representatives from the ATF, US Department of Justice, and local law enforcement from around the country, as well as additive manufacturing companies and other academics. "We are extremely proud and grateful for this partnership and look forward to its success," says Dettelbach.

The team continues to build a coalition to make these solutions a reality, including with Materialise, which produces back-end software for much of the industry. At the same time, engineering students in Thayer's two-term capstone course are determining how to best implement solutions. They are also examining how teens might be enticed to create 3D-printed objects with more positive social value. "Part of the problem is that boys are finding it enjoyable to produce and play with machineguns—it's giving them social capital, it's giving them a thrill," Diamond says. "It's not just the printer—it's society and people and culture and context. The technology is just the window dressing."

All of this makes MCDs an ideal real-life case study for students learning to harness the power of human-centered design to tackle multifaceted issues—in this case, making the difference between life and death. "With this project, we are building an inspirational case study for students to see that you need the humanities and social sciences in complex technical problem solving," Korsunskiy says. "For liberal arts students who may not be sure what value they can bring to the world, we are showing that the skills they are gaining at Dartmouth are crucial."

Michael Blanding is a Boston-based journalist whose work has appeared in WIRED, The New York Times, The Nation, and The Boston Globe Magazine.

Design Thinking for the Greater GoodThe MCD project isn't the only one using design thinking to impact the world. CEDC Director Monroe estimates about half of the engineering capstone projects each year partner with non-profits to design human-centered solutions for societal good. "Students are being equipped to be leaders in society and thinking how they can use their engineering tools to improve lives," she says. Recent projects include the following: BIKE WALK CENSUS TOOL Although cars are regularly counted for road usage patterns, pedestrians and cyclists are counted only sporadically through a time-consuming hand count process. Students developed an object detection algorithm to automatically count bikers and walkers to better design streets for their use. ARTERY ASSIST Despite placing 8 million arterial lines annually to treat US patients, healthcare professionals miss the mark more than a quarter of the time, requiring them to re-puncture the skin and distress their patients. This project developed a "stud finder" using an audio signal with LEDs and a laser pointer to more accurately identify the best place to stick. OPEN-SOURCE PFAS FILTER Toxic PFAS chemicals, known as "forever chemicals," increase risks for diseases such as cancer. Students created a low-cost wastewater filter for the carpet-cleaning industry that can remove 95 percent of PFAS from the water. NET-ZERO FARMHOUSE RETROFIT Although new construction is often created with sustainability in mind, existing housing can be left behind. This project took a rundown Upper Valley farmhouse and transformed it using solar panels and insulation to achieve net-zero energy use from the grid. BACKCOUNTRY MEDICINE Students are collaborating with the military to develop medical devices for remote locations, including an osteophone that uses sound to determine if a bone is broken and evacuation is needed. Another project aims to help emergency personnel better intubate a person by using chemical reactions to measure oxygen flow. EASY DE-ICING MINI-SPLIT HVAC systems are becoming more common; one problem, however, is that the outside compressor can freeze on cold days so it brings in cold instead of heat. Students are working to implement technology out of Thayer's Ice Research Lab that uses a pulse of electricity to efficiently de-ice surfaces. |

For contacts and other media information visit our Media Resources page.