- Undergraduate

Bachelor's Degrees

Bachelor of ArtsBachelor of EngineeringDual-Degree ProgramUndergraduate AdmissionsUndergraduate Experience

- Graduate

Graduate Experience

- Research

- Entrepreneurship

- Community

- About

-

Search

Professor Li guides her students in ENGS 33: Solid Mechanics as they design and build a scale model of a bridge that is stiff, strong, and economical. (Photo by Rob Strong)

Overview

Yan Li received her PhD degree in mechanical engineering from Georgia Institute of Technology in 2014. Prior to joining Dartmouth, she was an assistant professor of mechanical and aerospace engineering at California State University, Long Beach, and has been a faculty advisor for the Society of Women Engineering since 2014.

Li's research interests are in the area of mechanics of advanced materials, involving multiscale/ multiphysics modeling, integrated computational/ experimental approaches for next-generation materials design, and application of materials science and solid mechanics in advanced manufacturing. She has done research supported by the US Army Research Laboratory, Sandia National Laboratories, and NSF Center for Computational Materials Design, and has collaborated with industry partners including Boeing, Gulfstream, and GE.

Outside her lab and classroom, she enjoys classical music, reading, and exploring different cultures and food.

Research Interests

Multiscale and multiphysics modeling; multifunctional materials design and manufacturing; AI-enabled metamaterials for aerospace, energy, and healthcare applications; fracture/ fatigue analysis; process-microstructure-property-performance relation; data-driven materials design

Education

- BS, Mechanical Engineering, Yanshan University 2006

- MS, Material Science Engineering, Shanghai Jiao Tong University 2009

- PhD, Mechanical Engineering, Georgia Institute of Technology 2014

Awards

- Thayer Diversity and Inclusion Award, 2024

- Jubilee Global Diversity Award, 2023

- NH EPSCorR Pilot Award, 2020

- ASME ORR Early Career Award, 2020

- NSF Travel Award for Faculty Development Symposium, 2019

- NSF Travel Award for AISES National Conference, 2019

- NSF Travel Award for the National Diversity in STEM Conference, 2018

- NSF Travel Award for the Faculty Career Development Workshop, 2018

- Best Paper Award of the 8th International Conference on Computational Methods, 2018

- NSF Travel Award for LEVERAGE Summer Institute for Early Career Faculty, 2018

- NSF Travel award for Academic and Research Leadership (ARL) Symposium, 2018

- WAC Teaching Writing Fellow at California State University, Long Beach, 2017

- NSF Travel award for the Academic Leadership for Women in Engineering (ALWE) program, 2016

- Travel award for Professors Around the World at California State University, Long Beach, 2016

Professional Activities

- Society of Women Engineers (SWE)

- The American Ceramic Society (ACerS)

- Society for the Advancement of Material and Process Engineering (SAMPE)

Research Projects

-

Computational Material Design of Multi-objective Multiple Principal Element Alloys

Computational Material Design of Multi-objective Multiple Principal Element Alloys

The objective of this work is to develop AI-assisted computational tools to speed up the design and manufacturing of Multi-objective Multiple Principal Element Alloys.

-

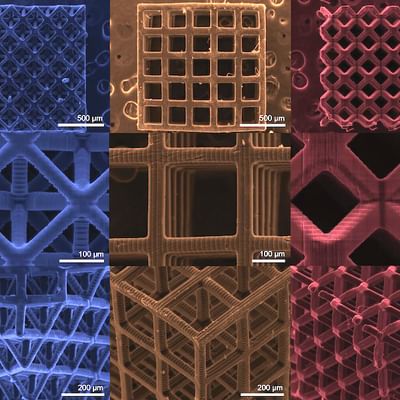

3D Printing of Zeolite Catalysts

3D Printing of Zeolite Catalysts

In this collaborative project, we developed a 3D printing approach capable of fabricating catalysts with enhanced surface area and high catalyst loading. This technology will pave the way for many catalytic activities, such as turning waste into jet fuel and removing greenhouse gas emissions.

-

Dynamic Observations of The Behavior of Snow/Ice Lenses Under Load

Dynamic Observations of The Behavior of Snow/Ice Lenses Under Load

The objective of this project is to elucidate the deformation behavior of snow specimens that contain either a weak snow layer or an ice lens at the microscopic level using advanced imaging techniques and simulation model.

-

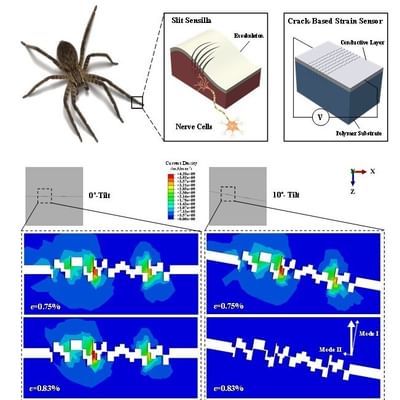

Explainable and Adaptable Artificial Intelligence for Advanced Manufacturing

Explainable and Adaptable Artificial Intelligence for Advanced Manufacturing

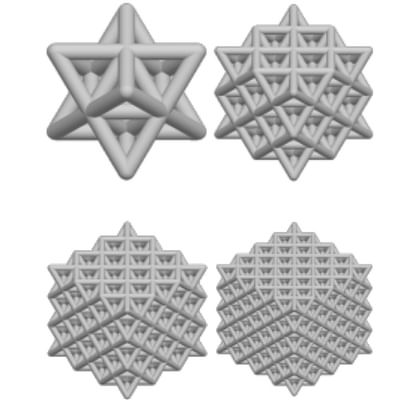

The objective of this project is to develop AI-assisted tools that enable explainable and adaptable metamaterial design and manufacturing.

-

High-Temperature Effective Piezoelectric Composites for Future Space Self-Powering Sensors

High-Temperature Effective Piezoelectric Composites for Future Space Self-Powering Sensors

The objective of this project is to develop 3D printable piezocomposites that can maintain excellent structural integrity under high temperature environments.

Selected Publications

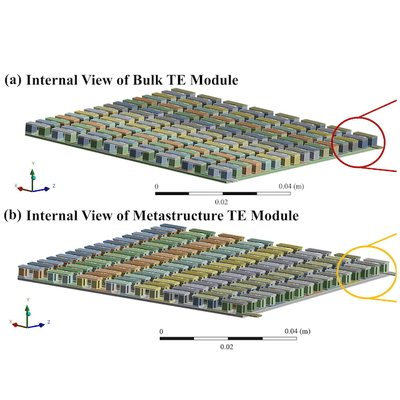

- Tang Y, Li Y. (2025) "A novel thermoelectric system for enhancing power generation from waste heat." Energy Conversion and Management. 344: 120262.

- Zhao H, Liu X, Tang Y, Kim A, Li Y. (2025) "A novel compressible piezocomposite design for acceleration and dynamic force sensing." Materials & Design. 257: 114492.

- Zhao H, Tang Y, Liu X, Kim A, Henry J, Li Y. (2025) "High-temperature piezoelectric composites with enhanced structural integrity." Ceramics International. 51: 23417–23424.

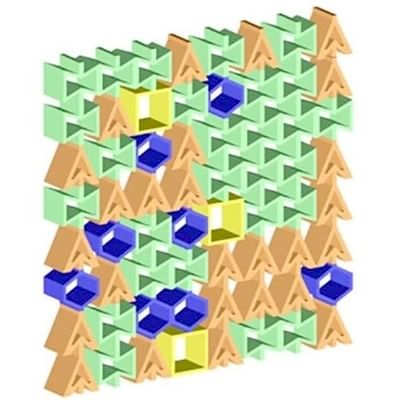

- Tang Y, Zhao H, Liu X, Henry J, Li Y. (2024) "Design of metamaterial thermoelectric generators for efficient energy harvesting." Energy Conversion and Management: X. 24: 100699.

- Liu X, Zhao H, Tang Y, Chen C, Zhu Y, Song B, Li Y. (2024) "Few-shot learning-based generative design of metamaterials with zero Poisson’s ratio." Materials & Design. 113224.

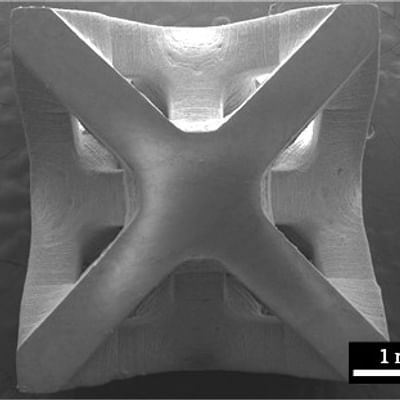

- Zhao H, Liu X, Li Y. (2024) "Architecture design of high-performance piezoelectric energy harvester with 3D metastructure substrate." Adv. Theory Simul. p2301214 [Featured as the cover].

- Karakaya K, Qian M, Zou R, Zhang W, Lu Z, Maiti D, Samanta A, Wan W, Liu X, Tiplea A, Li Y, Cui S, Wang C, Lei H, Bankston S, Yilmaz S, Chen J, Ozcan S. (2024) "3D printing synthesis of catalysts." Materials Today Sustainability. 100746.

- Tong X, Li Y, Fu M. (2024) "Modeling of grain size effects in progressive microforming using CPFEM." International Journal of Mechanical Sciences. 108971.

- Zhao H, Huddy J, Scheideler W, Li Y. (2023) "Rational design of 3D-printed metastructure-based pressure sensors." Journal of Advanced Engineering Materials. 2301056.

- Li Y, Cao J, Williams C. (2019) "Competing failure mechanisms in metal matrix composites and their effects on fracture toughness." Materialia. 5: 100238.

- Li Y, Zhou M. (2013) "Prediction of fracture toughness of ceramic composites as function of microstructure: I. Numerical simulations." Journal of the Mechanics and Physics of Solids. 61: 472–488.

- Li Y, Zhou M. (2013) "Prediction of fracture toughness of ceramic composites as function of microstructure: II. Analytical model." Journal of the Mechanics and Physics of Solids. 61: 489–503.

Books

Advances in Bioenergy

Elsevier Inc, 2023

Videos

Dynamic Motion Detection

Force Sensing

News