- Undergraduate

Bachelor's Degrees

Bachelor of ArtsBachelor of EngineeringDual-Degree ProgramUndergraduate AdmissionsUndergraduate Experience

- Graduate

Graduate Experience

- Research

- Entrepreneurship

- Community

- About

-

Search

Ian Baker

Sherman Fairchild Professor of Engineering

Senior Associate Dean, Research and Graduate Programs

Baker discusses his research, focusing on the properties and the mechanical and magnetic behavior of materials, and how this work can help power plants be much more energy efficient.

Research Interests

Materials for energy systems; mechanical behavior; phase transformations; electron microscopy; x-ray topography; x-ray diffraction; microstructure and mechanical behavior of snow, firn, and ice; magnetic materials; intermetallic compounds; high entropy alloys; high temperature materials; nanoparticles for magnetic hyperthermia; biomaterials

Education

- BA, Metallurgy and Science of Materials, University of Oxford 1979

- D.Phil, Metallurgy and Science of Materials, University of Oxford 1982

Awards

- Best Reviewer Award, Microstructures, 2022

- Outstanding Keynote Presentation Award, 5th International Conference on Materials Science and Smart Materials (UK), 2018

- Distinguished Award, 9th International Workshop on Advanced Materials (Yangzhou, PRC), 2016

- Fellow, American Association for the Advancement of Science (AAAS), 2015

- Fellow, Minerals, Metals & Materials Society (TMS), 2012

- Fellow, Materials Research Society, 2011

- Listed in ISI citation index of highly-cited Materials Scientists, 2003

- Fellow, The Institute of Materials, Minerals and Mining (UK), 2002

- Fellow, ASM international, 2001

- Chartered Engineer (C.Eng.) of The Engineering Council (UK), 1993

Professional Activities

- Field-Chief-Editor, Frontiers in Metals and Alloys (2022–)

- Co-Editor-in-Chief, High Entropy Alloys & Materials (2022–)

- Organizer, Physics and Chemistry of Ice, Dartmouth (2014)

- Organizer, MRS Fall Meeting Symposium on Intermetallic-based Alloys — Science, Technology, and Applications (2014)

- Editorial Board, Nano Life (2009–)

- Editorial Advisory Board, Intermetallics (1998–)

- Editorial Board, Metals (2010–)

- Editor in Chief, Materials Characterization (2009–2020)

- Editorial Board, International Materials Reviews (2002–2020)

- Reviewer for various US, Canadian, Hong Kong, Swiss, French, and Australian government agencies and numerous journals

- Consultant to various companies on microstructural characterization and materials processing

- Editor of the proceedings of five conferences

Research Projects

-

Creep of Antarctic firn

Creep of Antarctic firn

This work aims to understand the evolution of firn (multi-year snow) in the top layers of glaciers and ice sheets, applicable to understanding ice mass-balance from satellite data, estimating meltwater storage, and interpreting paleoclimate records from ice cores. In the Ice Research Lab, the firn cores are deformed using a creep jig, allowing the study of microstructural evolution and creep mechanics of the firn sample. After the deformation experiments are complete, the resulting firn samples will be analyzed using micro-CT imaging, SEM/ EBSD analysis, and Raman spectroscopy. The firn cores come from four different locations at Taylor Dome, Antarctica, and will complement a similar study done on firn from Summit, Greenland.

-

Impact of reinforcement on the behavior of ice under high strain rate loading

Impact of reinforcement on the behavior of ice under high strain rate loading

The compressive strength and fracture resistance of ice materials at high strain rates are critical for understanding dynamic ice failure in natural and engineered environments, including ice–structure interactions and impact events. Ice and frozen soils often contain entrapped colloidal minerals and fibrous organic materials, which are known to significantly affect the mechanical properties of ice under static loading. However, their influence under dynamic loading conditions has been the subject of limited study and remains poorly understood. In particular, high aspect ratio particles have been shown to inhibit crack propagation under static loading, suggesting that reinforcement may enhance fracture resistance in ice under dynamic loading events as well. We are investigating the effect of insoluble particulate and fibrous reinforcements on the compressive strength of ice at high strain rates. Reinforced ice specimens are being tested under high strain rate compressive loading using a Split Hopkinson Pressure Bar. Fracture behavior is being studied through high-speed imaging and post-mortem microstructural characterization to assess crack initiation and propagation mechanisms. The results will provide insight into how reinforcement influences the dynamic fracture processes in ice and frozen soils.

-

Sodium metal anodes

Sodium metal anodes

Sodium metal is an attractive anode for next‐generation energy storage systems owing toits high specific capacity, low cost, and high abundance. Nevertheless, uncontrolled sodium dendrite growth caused by the formation of unstable solid electrolyte interphase leads to poor cycling performance and severe safety concerns. To prevent the dendrite growth, we focus on approaches such as constructing an artificial solid electrolyte nterphase on sodium surface, employing a matrix material to cage sodium metal and tuning the electrolyte compositions.

-

Interstitial strengthening in f.c.c. high-entropy alloys

Interstitial strengthening in f.c.c. high-entropy alloys

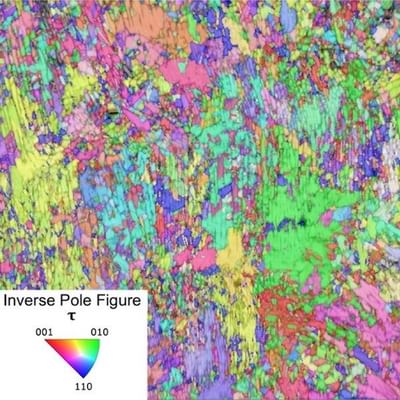

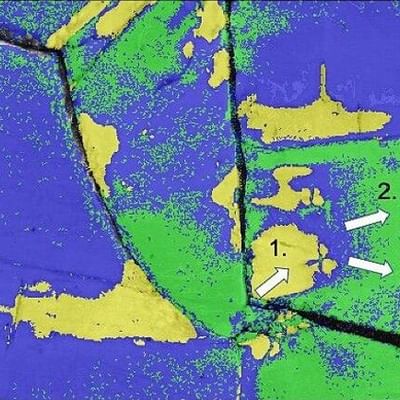

The aim of the project is to understand both the phenomenology and micromechanisms of interstitial strengthening in f.c.c. high entropy alloys (HEA) and medium entropy alloys (MEAs). The working hypothesis is that interstitials have substantial effects on dislocation behavior (and, hence, mechanical properties) by changing slip from wavy to planar due to an increase in the friction stress (possibly due to short-range order, SRO), or a change in the stacking fault energy (SFE). To that end, the project will: determine the effects of interstitials on the stress-strain curves of single-slip-oriented single crystals, followed by post-mortem examination, using a TEM and an SEM, of the defect structure of crystals strained to various elongations; perform in situ deformation experiments in a TEM and an SEM, and use neutron diffraction to determine the dislocation behavior in detail; determine, using X-ray diffraction (XRD), STEM (including electron diffraction and X-ray spectroscopy), and atom probe tomography (APT), the effects of interstitials on the lattice (the size mismatch parameter, the modulus mismatch parameter, SFE, SRO) and their segregation to dislocations both before and after straining; and determine the exponents in the relationships between the increase in yield strength and both the interstitial concentration and the mismatch parameters. The work will be performed on the HEA/MEAs Fe40Mn40Co10Cr10 and CoCr0.25FeMnNi doped with various interstitials, and, time permitting, Fe40.4Ni11.3Mn34.8Al7.5Cr6. The work will involve synchrotron XRD measurements at the Argonne National Laboratory, and both in situ straining neutron diffraction studies and APT studies at the Oak Ridge National Laboratory.

-

Fabrication of columnar‑grained microstructures and single crystals via directional recrystallization of additively‑manufactured nickel‑based alloys

Fabrication of columnar‑grained microstructures and single crystals via directional recrystallization of additively‑manufactured nickel‑based alloys

Ni-based superalloys were developed in the 1940s and have been continuously improved ever since, culminating in the current single-crystal jet turbine blades made by directional solidification. However, the cost of such turbine blades exceeds $15,000 and replacement costs when a jet engine is overhauled can be hundreds of thousands to millions of dollars. Thus, a cost-effective method of producing Ni-based superalloy turbine blades is imperative. In this project, we will produce columnar-grained structures or single crystals of nickel alloys by directional recrystallization (DR), a solid-state process, of additively manufactured (AM) material, in which the complex structures are built layer-by-layer by powder fusion. The goal is to investigate if production of a single crystal Ni-based superalloy turbine blade is feasible via the integrated route of AM and DR, and to understand the physics underlying such a processing route. The technology, although focused on Ni alloys, is nonspecific and could be used for other materials, and easily scaled up. We will also develop a web site describing DR of AM materials and develop an undergraduate laboratory project.

-

High entropy alloy soft magnets

High entropy alloy soft magnets

Soft magnets play a vital role in efficient energy conversion in a variety of important applications and industries including wide-bandgap semiconductors, electric vehicles, aeronautics, and aerospace, particularly at high temperatures. Improving the efficiency of modern power electronics and electrical machines via advanced soft magnets has the potential to significantly contribute to global energy savings, thereby leading to a reduction of the associated carbon footprint. In this project, we are working on two novel FeCoMnAl high-entropy alloy (HEA) soft magnets, one of which is single-phase B2 (Fe30Co40Mn15Al15) and the other consists of an ordered B2-phase matrix enriched with Co/Al and uniformly distributed BCC nanoprecipitates enriched with Fe/Mn (Fe40Co30Mn15Al15). The two HEAs show similar properties, viz., a high saturation magnetization of 158-162 Am2 kg-1, a high Curie temperature of 1020-1081 K, a low coercivity of 108-114 A m-1, a high electrical resistivity of ~230 µΩ cm, and good thermal stability. We are processing these HEAs using both a powder metallurgy route and via additive manufacturing. The magnetic properties and microstructures of the resulting materials are being examined using combination of a VSM, TEM, SEM and XRD examinations.

-

Biodegradable zinc alloys for orthopedic implants

Biodegradable zinc alloys for orthopedic implants

Orthopedic implants are widely used to treat bone and joint disorders, such as fractures, osteoarthritis, and spinal deformities. However, conventional implant materials, such as stainless steel, titanium, and cobalt-chromium alloys, have several limitations: (i) they may cause adverse reactions and metal sensitivity due to their foreign ions and corrosion products; (ii) they may fail prematurely due to stress concentration and fatigue; (iii) they may interfere with bone remodeling and healing due to their mismatched mechanical properties with the host tissue; (iv) they can become a nidus for bacterial infection and biofilm colonization. Therefore, there is a need for novel implant materials that can overcome these challenges and improve the clinical outcomes of orthopedic surgery. Zinc is an attractive candidate for orthopedic implants because it is an essential trace element in the human body that plays a key role in bone metabolism and wound healing. Moreover, Zn is biodegradable and can be gradually resorbed by the body without leaving any permanent foreign material. The typical in vivo corrosion rates of unalloyed zinc in rats is 0.03 mm/yr, which is a useful rate for biodegradation. However, unalloyed Zn has very poor mechanical strength, which limits its application as an implant material. To address these issues, we are developing new Zn-based alloy that contains small amounts of silver, calcium, iron, magnesium, and manganese, and using a novel processing route. These alloying elements are chosen based on their beneficial effects on the biological and mechanical properties of Zn. Specifically, Ag has antibacterial activity and can reduce the risk of infection; Ca can promote bone formation and integration; Fe can enhance fracture fixation and blood compatibility; Mg can improve biocompatibility and corrosion resistance; Mn can increase ductility and strength. An adequate rate of implant degradation will allow the bone to heal properly before degrading and allowing the bone to support any loads.

-

Observations and micromechanical modeling of the behavior of snow/ice lenses under load in order to understand avalanche nucleation

Observations and micromechanical modeling of the behavior of snow/ice lenses under load in order to understand avalanche nucleation

The microstructual evolution of snow under a temperature gradient has been of interest for many years since this can lead to persistent weak layers, which are possible microstructural causes of avalanches. Ice crusts can form on top or within a snowpack from a variety of meteorological conditions including significant melt/freeze or freezing rain events, and once buried, they can persist throughout the entire winter season and act as an ideal sliding surface for dangerous slab avalanches in seasonal mountain snowpacks. Both of these phenomena are important because the number of fatalities from avalanches in the US has increased annually since the 1970s. Avalanches can also have substantial economic impacts due to road closures, the costs of rescue and building damage, and, with continued global warning, more avalanches are expected in Arctic regions. To understand avalanche nucleation, we are deforming two types of specimens (heterogeneously-layered snow and snow containing an ice lens) in a micro CT located in a cold room, in which the specimens are repeatedly imaged during loading. We are also performing more macroscopic deformation experiments on larger samples at both different rates and different temperatures, which are imaged using a high-speed video camera during loading. The final deformed microstructures in both cases are imaged at high resolution using a scanning electron microscope, which provides information on both the effects of crystal orientation on deformation while clearly delineating one ice crystal orientation from another. Based on the experimental observations, a multiscale computational model is being built to understand crack initiation/crack propagation as well as the deformation mechanisms in heterogenously-layered snow samples containing persistent weak layers and ice/snow interfaces.

-

Porous thermoelectric cells (TECs) for waste heat recovery

Porous thermoelectric cells (TECs) for waste heat recovery

Porous thermoelectric cells (TECs) are being developed for waste heat recovery. This project seeks to convert waste thermal energy directly into electricity potentially increasing overall energy efficiency by 15-20% and providing new portable electric power sources, particularly for cold regions. The project is focusing on low cost, nanostructure-engineered TEC (NETECs) materials based on earth-abundant, highly machinable metallic alloys and intermetallic compounds by engineering the grain sizes, second phase precipitation, and nanopores in transition metal intermetallic compounds. The project is currently focusing on the compound Fe2AlV. The location of quaternary atoms in the lattice is being determined by the TEM-based technique ALCHEMI.

Funded by USA-CRREL

Selected Publications

- Interstitials in compositionally complex alloys, Ian Baker, Blazej Grabowski, Sergiy Divinski, Xi Zhang and Yuji Ikeda, Materials Research Society Bulletin, 48 (2023) 769–776. (INVITED) https://doi.org/10.1557/s43577-023-00558-9

- Mechanical Properties of Freshwater Ice, Ian Baker and Ayobami O. Ogunmolasuyi, The Journal of Physical Chemistry C, 128(51) (2024) 21609-21626. (INVITED) DOI: 10.1021/acs.jpcc.4c05171

- Additive manufacturing of Mn-Al permanent magnets via laser powder bed fusion, Thomas Keller, Wuxian Yang, Wen Chen and Ian Baker, Materialia, 33 (2024) 101978. https://doi.org/10.1016/j.mtla.2023.101978

- Suppression of anti-phase boundary defects in Mn-Al-Ti permanent magnets, Thomas Keller, Dylan Barbagallo, Tushar Kanti Gosh, Natalya Sheremetyeva, Geoffroy Hautier and Ian Baker, Acta Materialia, 265 (2024) 119646. https://doi.org/10.1016/j.actamat.2023.119646

- Alternating magnetic field guiding system for MNP hyperthermia treatment of deep-seated cancers, Robert V. Stigliano, Ilona Danelyan, Giga Gabriadze, Levan Shoshiashvili, Ian Baker, P. Jack Hoopes, Roman Jobava and Fridon Shubitidze, International Journal of Hyperthermia, 41 (2024) 2391008. https://doi.org/10.1080/02656736.2024.2391008

- Severe plastic deformation of Mn-Al permanent magnets, Thomas Keller, Gheorghe Gurau and Ian Baker, Materialia, 38 (2024) 102251. https://doi.org/10.1016/j.mtla.2024.102251

- Comparison of the dry-sliding wear behavior of a nitrided and as-cast two-phase Fe28.2Ni18.8Mn32.9Al14.1Cr6, Aubrey Tang, Nicolaus Dahl, Francis E. Kennedy and Ian Baker, High Entropy Alloys & Materials, (2025). https://doi.org/10.1007/s44210-025-00069-z

- Cold Working and Annealing Enhanced Cyclic Thermal Stability of Native Oxide Solar Thermal Absorbers on a FeMnNiAlCr High Entropy Alloy, Xiaoxue Gao, Edwin Jiang, Andrew Pike, Shang Liu, Geoffroy T. F. Hautier, Ian Baker and Jifeng Liu, High Entropy Alloys Mater. 3, 371–386 (2025). https://doi.org/10.1007/s44210-025-00072-4

- Elevated Temperature Creep of a Eutectic FeNiMnAlCr High Entropy Alloy, Edwin Jiang, Jifeng Liu and Ian Baker, High Entropy Alloys and Materials (2026). https://doi.org/10.1007/s44210-025-00077-z

- Observations of creep of polar firn at different temperatures, Yuan Li, Kaitlin Keegan and Ian Baker, The Cryosphere. https://doi.org/10.5194/egusphere-2024-2337

Patents

- High-entropy alloys with high strength | 11530468

- Oxidation resistant high-entropy alloys | 10190197

- Nanostructured Mn-Al permanent magnets and methods of producing same | 8999233

- Joining of parts via magnetic heating of metal aluminum powders | 8444045

- Joining of parts via magnetic heating of metal-aluminum powders | 8172126

- System and method for use of nanoparticles in imaging and temperature measurement | 7994786

- High-strength nanostructured alloys | 7815850

Books

Fifty Materials That Make the World

Springer, 2018

Videos

Graduate Student Engineering Research: Eutectic Alloys

Seminar: Materials Characterization

Lecture: Nanotechnology and its Future Role in Medicine

News

In the News

The Business of Materials

High-Entropy Alloys, Additive Manufacturing, and Ice Mechanics

Nov 17, 2025

High-Entropy Alloys, Additive Manufacturing, and Ice Mechanics

Nov 17, 2025

Solar Power Investor

Dartmouth receives a $750,000 grant from the Department of Energy for a new solar technology research project

Aug 18, 2020

Dartmouth receives a $750,000 grant from the Department of Energy for a new solar technology research project

Aug 18, 2020