- Undergraduate

Bachelor's Degrees

Bachelor of ArtsBachelor of EngineeringDual-Degree ProgramUndergraduate AdmissionsUndergraduate Experience

- Graduate

Graduate Experience

- Research

- Entrepreneurship

- Community

- About

-

Search

All Thayer News

Dartmouth Engineering Receives DOE Funding for Developing Printed Solar Cells

Feb 14, 2024 | by Catha Mayor

Assistant Professor of Engineering William Scheideler was awarded $250,000 by the US Department of Energy (DOE) Small Innovative Projects in Solar (SIPS) Program. The funding will go toward his lab developing a new method for fast and scalable manufacturing of reliable perovskite solar modules.

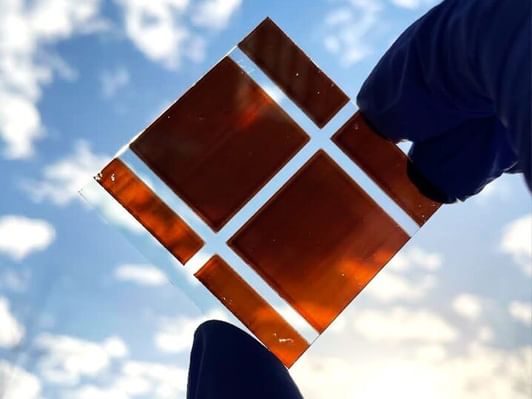

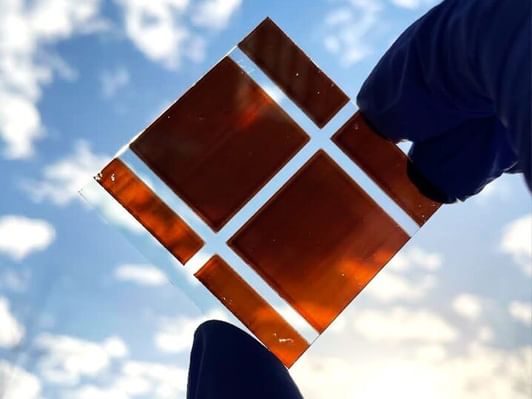

Printed perovskite absorber films for solar modules. (Photo by Julia Huddy)

"Silicon solar cells haven't changed much in decades and we're running up against their fundamental limits," says Professor Scheideler. "Using a different solar absorber material could lower the cost of solar energy while also improving performance. We're using a thin film perovskite material that's intrinsically well-suited for scaling up to meter-wide panels, but the challenge is figuring out how to make them stable. Scaling and stability are the two fundamental challenges, and we're trying to address both."

The SIPS Program, run by DOE's Solar Energy Technologies Office (SETO), funds research projects in photovoltaics that are riskier than ideas based on established technologies, but that can quickly validate novel concepts and lay the foundation for continued research. Scheideler's project—called "Self-Leveling Inks for Printing Ultra-uniform Perovskite Solar Modules by Flexography"—will work toward developing printed perovskite solar modules that do not require laser-carved pathways to connect adjacent cells. The material's high uniformity plus avoidance of damage from laser blasting are critical for the long-term operational stability of perovskite cells and modules.

"Today, the way you would make a large thin-film module commercially is to take a monolithic film and use a laser to remove the material between each cell," explains Scheideler. "But removing the material also damages it, and the chemical reactions that degrade the module are seeded from those points. We're doing it quite differently. Instead, we add the cell pattern directly during printing. The same way you can print a pattern on paper, you can pattern the solar absorber material with the features you need to interconnect the cells, rather than using a laser."

Another important factor for long-term device stability is controlling the uniformity of the perovskite's crystallization, which Scheideler aims to achieve by designing self-leveling inks. "These solar cells are less than a micron thick—which makes printing challenging," he explains. "The liquid ink, by default, has perturbations on its surface, like ripples on a pond. To get nanometer-level uniformity, we have to engineer the viscosity and surface tension of the ink in such a way that it drives the film to a level state. In other words, we want the kind of ink that heals itself, because if you have even one microscopic pinhole, that's enough to ruin the performance of a meter-wide solar module."

For contacts and other media information visit our Media Resources page.