- Undergraduate

Bachelor's Degrees

Bachelor of ArtsBachelor of EngineeringDual-Degree ProgramUndergraduate AdmissionsUndergraduate Experience

- Graduate

Graduate Experience

- Research

- Entrepreneurship

- Community

- About

-

Search

All Thayer News

Student Project Highlight: A planet-friendly packable fridge

Jul 15, 2025 | by Ivie Aiwuyo '26

Master of Engineering (MEng) students Monica Scotto Th'25, Isabelle Anderson Th'25, and Felix Hoehner Th'25 took ENGM 191: Product Design and Development and used human-centered product design methods to invent and build "Pufferfish," a packable, powered, planet-friendly cooling solution.

Transcript

Felix: So we were taking ENGM 191: Product Design and Development, and the way the class was structured, was making us come up with ideas that could impact people's lives.

Monica: The pufferfish is a packable, powered, planet-friendly cooling solution. It's composed of recycled thermoplastics, and HFO spray foam, which is minimally impactful to the environment, displacing those garage refrigerators and single-time-use styrofoam chillers that you just throw away after one use.

Isabelle: We went through product design and development, and throughout the class, it went from kind of a fun idea that we all had together into, maybe we could really make something out of this. So we began prototyping in the Fall term. In our class, we had some very basic low, low fidelity prototypes out of cardboard so we could see the size, some 3D-printed models that were an eighth of the scale of the real versions. We started after basic drawings and CAD models, into light prototypes, and then we continued that into a full-size prototype. We're hoping to get it to function both in wall outlets in your home and in a car for camping or RVs, things like that. So it's a very versatile solution, and the most distinguishing feature of it being a fridge is it collapses down to over less than half of its size.

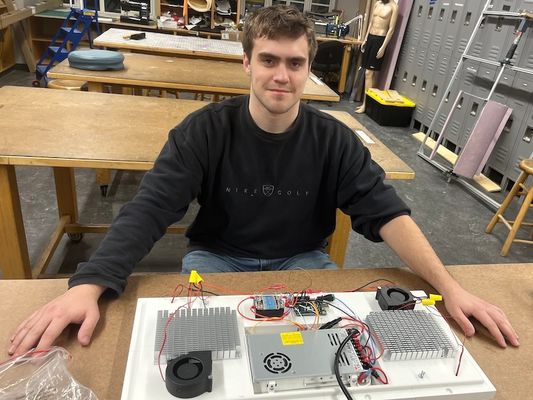

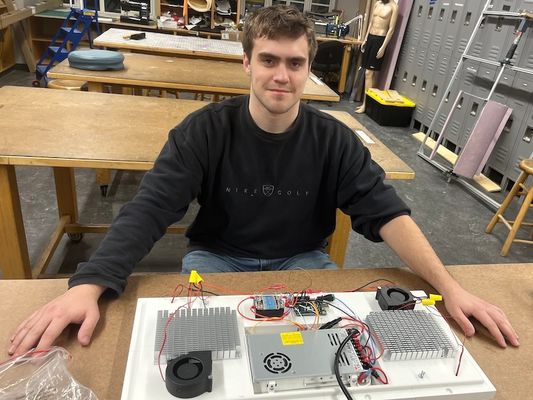

Felix Hoehner Th'25 with the Pufferfish electronics.

Monica: The human-centered product design course gave us this framework in which to operate. We're not creating a product for the sake of engineering brilliance or technical complexity. We're building something because it's going to change the way people live and inherently improve their quality of life.

Isabelle: We all have similar and different backgrounds. Similar in we're all very passionate, hardworking people, and different in I'm mechanical, Felix is aerospace, Monica is physics, going into law.

Monica: I like to think of us like a soccer team, right. So Felix is sort of the nitty gritty engineer, the midfielder. Izzy is, I would equate to, more of a goalie who really makes sure our technology is sound as a whole. And, whereas, I think of myself more of the forward taking all of their work that they've put and get that interest generated from various investors.

Felix: Having different backgrounds definitely just gives us a wider breadth of knowledge and different angles that we can tackle these problems from.

Isabelle: Planning and building a company is something I've never imagined I'd be doing. So that's quite the jump, for me anyway. But I think even in our course with Dr. Murnane—Product Design and Development—we got the basis of financial models and team dynamics, things like that, that kind of helped us jump into all the legal aspects of building a company.

Felix: A lot of times students get discouraged in terms of, they might have a cool idea, but maybe they don't think it's cool enough, or maybe they don't think that they'll be taken seriously because they're just students. And I haven't found that at all at Dartmouth.

The professor we originally took the class with ended up becoming our closest advisor, and she's just shown us all these different possibilities. Everyone we've talked to here at Dartmouth has taken us with the most respect and also sincerity towards our product, and they share the drive to create something to help people. I think that's been very, very moving and also very important to us.

For contacts and other media information visit our Media Resources page.