- Undergraduate

Bachelor's Degrees

Bachelor of ArtsBachelor of EngineeringDual-Degree ProgramUndergraduate AdmissionsUndergraduate Experience

- Graduate

Graduate Experience

- Research

- Entrepreneurship

- Community

- About

-

Search

All Thayer News

A New Way to Engineer the Structure of Metals Comes to Dartmouth

Aug 06, 2025 | by Catha Mayor

A team of engineers has invented a technique to tailor the structural design of metals down to the microscale. The ability to precisely control the microstructure of metal alloys has the potential to revolutionize the manufacturing and performance of sensors, magnets, robotics, biomedical implants, microelectronics, and more. Plans are already underway to partner with the Power Management Integration Center at Dartmouth that's working to address a range of challenges facing next-generation power electronics.

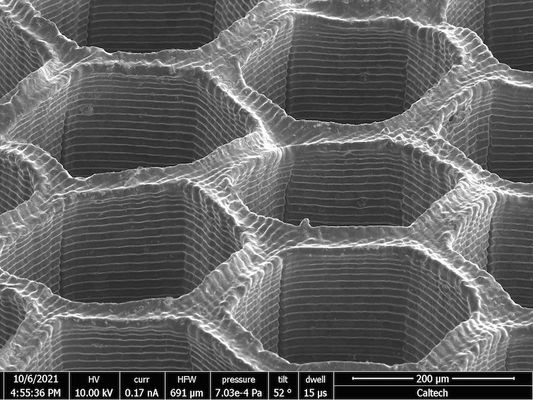

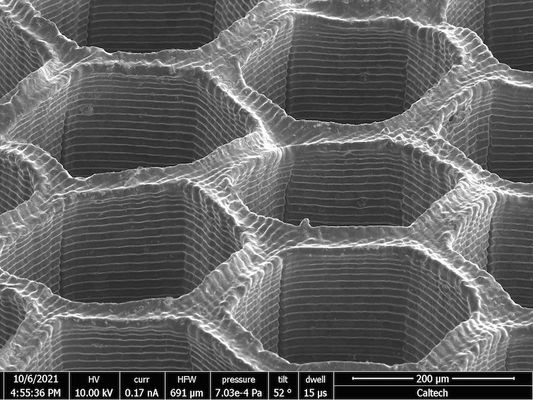

The final step in HIAM removes oxygen, leaving a mostly dense copper-nickel alloy in the desired, 3D-printed configuration. Here, a honeycomb structure was selected. (Image by Thomas Tran/Caltech)

"There are many reasons why we want to make and control the properties of metals at the microscale. But it's really difficult with the existing methods, both for traditional and additive manufacturing," said Rebecca Gallivan, a Dartmouth Engineering professor and coauthor of a new study conducted with colleagues at Caltech and published in the journal Small. "For example, if we want to advance microelectronics, small scale robotics, or put new things in our bodies, we need control over their shapes in that microscale regime."

The study demonstrates the ability to fine-tune a metal's internal structure that helps determine its properties and enable new technologies and applications. The team used a well-known copper-nickel alloy commonly used for anti-corrosion applications. "The technique we've developed can create this really interesting internal structure that's different than the structure made by other additive techniques that use the same chemistry," explained Gallivan.

The technique, called hydrogel-infusion additive manufacturing (HIAM), uses stereolithography—a standard 3D-printing technology for making things like dental molds. "We use that as a platform for an innovative processing method where we infuse the metal salts into the printed scaffold and then basically burn it all off," said Gallivan. "And what you're left with is your metal, your alloy, or your ceramic in that same geometry."

Developing a process that controls the geometry separately from the chemistry means the technique can work for a range of different materials, including ones like copper and tungsten that don't respond well to conventional additive manufacturing methods. Additional potential benefits are wide-ranging—enhancing the functionality and efficiency of electronics and sensors, making medical implants smaller and less invasive, increasing power without increasing size, and eliminating the toxic solvents and chemicals that are often used in microprocessing plants.

"We also don't have a lot of waste or scrap," added Gallivan. "If we're thinking about precious materials, things that are difficult to source or that have supply chain challenges, this technique could avoid the need for recycling waste or excess material."

Coauthors l to r: Dartmouth Engineering professor Rebecca Gallivan, Caltech PhD graduate Thomas Tran, and Julia Greer, professor of materials science, mechanics and medical engineering at Caltech.

Gallivan sees the published study as foundational for the next steps in terms of both research and design. "My research group is going to continue to use and develop this technique. We're really interested in microelectronics, and we've got some awesome people here who work in that space. I'm excited to see how we can help tackle current material and processing limitations and improve rapid prototyping."

Gallivan's group is also interested in photonics and exploring how they can design materials to interact with light for applications such as telecommunications. "Nanosale printing would use the same concepts, but scaled-down."

In addition to the obvious practical applications, Gallivan is looking forward to discovering more about the basics of mechanical behavior of materials. "There's a lot of fun questions to dig into as we develop more and more alloys—How are they similar? What's universal in how materials deform? How might we break away from some of the traditional engineering trade-offs or limitations by designing at the nanoscale?"

The way scientific discovery inevitably leads to more questions is a clear source of joy, and when asked why she chose to focus on materials science as an engineer, Gallivan smiled. "I like to say two things," she mused. "One, everyone is a materials scientist, whether they know it or not, because that's how we experience our world. Materials science and engineering is just the language that helps us connect what the atoms are doing to what our experience is. And two, most of the big problems we need to tackle as a society are materials problems. Energy, that's a materials problem. Medicine, that has major materials problems. So that's what I love about materials engineering—you sit at the center of helping to solve so many different kinds of problems."

For contacts and other media information visit our Media Resources page.